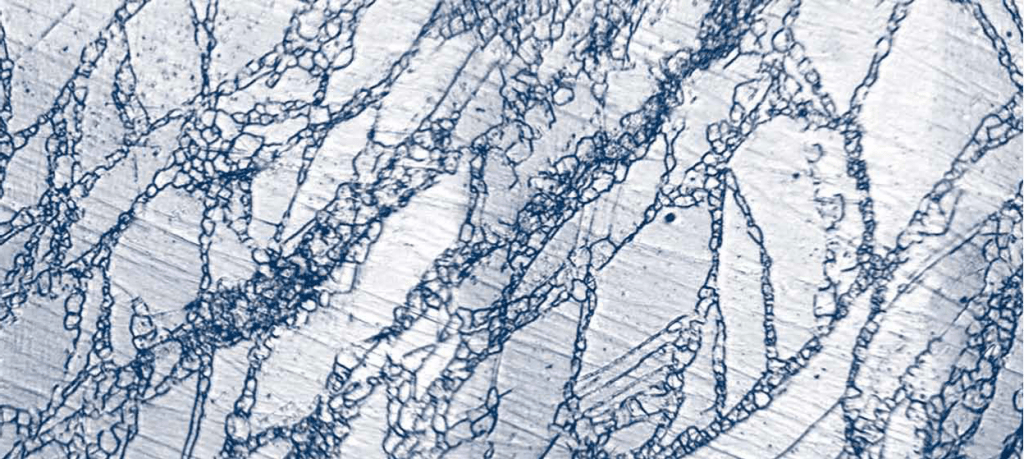

Our materials expertise in the field of forming technology is the core of our success

Since its establishment, GMT has been working in the two fields of research and in the metal processing industry. Therefore, you receive and acquire theoretical correlations at GMT; in addition you are competently accompanied to apply this knowledge on an industrial scale. The following services can be requested from us:

Consultation on the development and use of new grades or alloys made of steel, titanium, aluminum, nickel-based, cobalt, magnesium, molybdenum, etc.

Planning of tests for material data determination and interpretation of material data (e.g. mechanical properties, microstructure, static and dynamic recrystallization)

Model creation for microstructure development incl. phase transformation, CCT diagrams

Flow curves: planning of tests and experimental determination, approximation of flow curves based on experimental data

Recrystallization model: planning of tests and experimental investigation of recrystallization behavior, determination of material-dependent coefficients

Thermal physics: planning of tests and experimental determination of material parameters with regard to thermo-physical properties

Selection of suitable material data for simulation and support in interpreting simulation results of forming and heat treatment processes

Design and optimization of heating and heat treatment processes (quenching and tempering / hardening)

Additive manufacturing: Integration of CCT diagrams and creation of transformation models for innovative processes

Benefit from our applied materials expertise!

MatILDa

MatILDa supports the realistic simulation of material behavior in forming processes and during heat treatments.

Materials

Combining all common steels and material alloys in one place as a basis for the various areas of application